Why CNC ONE MAX?

Our vision is simple: offer the best machine in its class. With MAX we want to awaken the true creative abilities in makers/craftsmen ranging from beginners to professionals by giving them a reliable and powerful CNC, that is controlled by an easy to use and state of the art control software.

Furthermore we want to allow everyone, including absolute beginners, to be creative, realize large and repeatable projects in their workshop.

Mechanics

MAX is designed and built in Germany with the mission of bringing hi-tech manufacturing to everyday people. With a repeatable precision of 0.01 mm on a huge 1x1 meter work area. The superior performance of CNC ONE MAX comes from the combination of the following features:

BACKLASH-FREE BALLSCREWS

Other companies tend to use leadscrews as their drive mechanism or even worse: timing belts. Unfortunately, these are very cheap components that result in poor quality machine operation.

Every axis on CNC ONE MAX machines is equipped with our backlash-free ball screws, which we individually test for precision.

HIGH QUALITY LINEAR RAILS

CNC ONE linear rails provide linear motion by re-circulating rolling precision balls between a profiled rail and a bearing block. The coefficient of friction on CNC ONE rails is 50 times better compared to a traditional slide and they are able to take high loads in all directions. With these features, CNC ONE linear rails can achieve extreme precision and greatly enhanced moving accuracy.

HEAVY DESIGN

MAX is built with a thick and rigid structure to achieve superior precision. The new X and Y axis profile are updated to be 2x heavier than previous CNC ONE machines. The front and the back of the machine frame is made of one continuous steel plate

This adds up to a weight of 120-130kg and makes MAX up to 3x heavier than other CNC machines which are double in price!

Electronics

With advanced features designed for precision, real-time monitoring, and seamless control, this equipment makes your machining experience smoother, smarter, and more efficient.

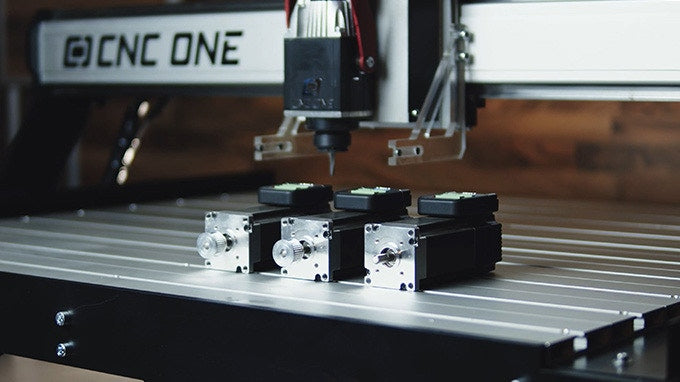

CLOSED-LOOP SERVO MOTORS

MAX is equipped with advanced closed-loop servo motors, offering consistent torque and virtually eliminating the risk of losing steps. These servos are fully integrated with the machine’s feedback system, ensuring that if an error occurs, the machine doesn’t continue cutting—it stops immediately, preventing damage to your workpiece or the machine itself.

CLEAR STATUS INDICATORS AT EVERY STEP

All key components, from the servos to the inductive switches and Z-probe, are equipped with status LEDs. At a glance, you can see the exact state of the machine—whether it’s homed, actively milling, paused, or in an emergency stop mode. The control cabinet features status LEDs for every actuator, sensor input, and output, allowing for quick diagnostics and reducing downtime.

Our plug-and-play system, incorrect connections are practically impossible, ensuring a smooth and error-free installation process every time.

FLEXIBLE CONTROL OPTIONS

Our machine offers various control options to suit your preferences. A native touchscreen interface comes standard, providing an intuitive and efficient way to operate the machine. Additionally, you can connect a keyboard or controller for even more versatility, allowing you to choose the control method that fits your workflow best.

Software

We understand that seamless software integration is key to an efficient CNC experience. That’s why we use LinuxCNC, which runs natively on our control system. You no longer need to rely on your PC to control a CNC machine— this often cluttering your system during milling—we’ve eliminated that problem entirely! With our solution, your PC stays clean and efficient throughout the process.

MODERN AND CUSTOMIZABLE WITH LINUX CNC

With LinuxCNC running directly on the machine, your PC stays free for other tasks. You can create custom macros and integrate additional hardware It’s perfect for users who want flexibility and control over their machine’s capabilities. Our system also allows you to operate the machine via touch, providing a sleek, modern, and intuitive experience

Exclusive Access to the CNC ONE HUB

Every CNC ONE customer gains access to CNC ONE HUB, a cloud-based platform for securely storing and managing projects. No more running back and forth with USB sticks—your files are securely saved in the cloud, accessible from any device.

Integrated with LinuxCNC, it simplifies file exports and data management. offer automatic export for your designs, complete with smart naming of project files. You’ll never need to worry about naming files “v1,” “v2,” or “final final” again.

Hub not only makes file management easier and more efficient but also adds a layer of enjoyment to the process!

Have A Question?

Our Team will always be here to help at every stage of your CNC Journey. Please see our FAQ page for some quick answers to common questions. Otherwise, feel free to get in touch at any time. We'll give you our honest opinion and bring no sales pressure.