If you're finally serious about monetizing your passion as a maker:

Let's explore the 3 STEPS to build a meaningful business you could be proud of,

using CNC ONE MAX.

Step 1: Choose HOW To Sell

Local and Online Marketplaces

Great for getting sales when you’re starting out and can remain a great source of revenue as your business grows.

Selling your builds at local farmers markets or Facebook Marketplace could be a great way to pay off your machine and bring in revenue as you get the ball rolling in online sales.

Etsy, Facebook Marketplace, Ebay, and even Amazon are all great places to list your builds. When you start out, you can "mill on demand". Essentially, just wait till an order comes in, then produce the product afterward. But, inevitably as you begin to get consistent sales, you'll probably want to have a stock of inventory.

Online market places are the fastest way to get your products out there. It's a great way to test product ideas. But, the challenge is always the fact that your competition's product is listed right there next to yours.

Take Custom Orders

Selling custom versions of your existing standard products could help you increase average order value, this is strongly worth considering.

A popular approach to selling custom products to create product prototypes. Many businesses are looking to form relationships with CNC businesses to help them create prototypes.

Building a relationship with your customers is a huge part of selling custom products. This will keep them coming back for more, plus recommending your service to others.

Build A Brand

The best way to scale a CNC Consumer Products Business is to build a brand. Use your CNC machine to build parts for your products.

In building a brand, your customers don't necessarily care about the tools you use to manufacture a product. They care more about the values your brand stands for and how your products make them feel.

Remember, as a brand, you are the representative of your audience’s values. Don't try to sell your product, instead show your audience what their life can be like when they live with your product.

Build a website and use social media to tell the story of the lifestyle your audience will experience once they own your product. Sell this dream. (Of course, the dream can only be achieved when they own your product!)

Sell To Businesses

Companies need parts for their products. That's where you come in.

When you sell parts or finished products to businesses, you could do things like create monthly purchase agreements or have minimum order quantities.

The best part about this method is you only need a handful of customers to hit your revenue targets. You'll be able to just focus on production, quality control and deliveries, and not worry so much about sales and marketing.

Trade shows may be one of the easiest ways to create a list of leads and find your first customers. You’ll want to look for industry specific business to business trade shows. At these shows you can typically find owners, managers, or high level representatives of companies. They are there to look for new opportunities for their businesses and will welcome your approach.

Step 2: Choose WHAT To Sell

No. 1

House Numbers

Home renovations are all about the details, and you know how obsessed people get about their home remodels. Once they see your custom house numbers, there's no going back.

No. 2

Wood Trays

Everyone need places to put things. Perfect for night stands or coffee tables. It seems like walnut wood trays are very popular choice for consumers.

No. 3

Knife Scales

Knife enthusiasts love to customize their pocket cutting gadgets. The interesting thing about the knife world is that consumers are willing to spend a lot for the satisfaction of carrying the perfect knife.

No. 4

Forged Carbon Fiber

Carbon fiber parts with a CNC machine?! Yep! By using your machine to build a mold, you could make forged carbon parts. These parts are popular in cars, motorcycles, and bicycles.

No. 5

Woodworking Templates

Woodworkers use templates to make their work quick and repeatable. Maybe they should just get a CNC! But for now they'll have to buy your template designs to get the work done.

No. 6

Tool Organizers

When you sell organization, you are actually selling time savings. Think of how many workshops could benefit if they had a better system to keep them from losing tools.

No. 7

Aluminum Car Emblems

Race car, Vintage car, and Tesla fan boys all need some extra personalization to make the ride truly unique.

No. 8

Brass Belt Buckles

A proper belt buckle can be owned for a lifetime and passed down for many more. Consumers are willing to pay a premium for a quality item they are proud to own.

No. 9

Metal Card Wallets

Metal card wallets are enormously popular. But not many are seriously making high end or custom versions of this product. It seems like a great opportunity to target the EDC space with.

No. 10

Wooden Signs

Every business needs a good sign. If you can make them look good, the value will be immediately obvious making this an easy sell.

No. 11

Desk Organizers

Consumers are obsessed with their desks and work stations. Don't believe it? Just search YouTube where you'll find 1000's of videos with millions of views on this topic. Give them what they want.

No. 12

Aluminum EDC Boxes

An Altoids Tin to put your EDC items? It's practical! But you will put it to shame with a custom made aluminum EDC box... Tip: Mill holes for magnets on the top and bottom to keep it shut.

No. 13

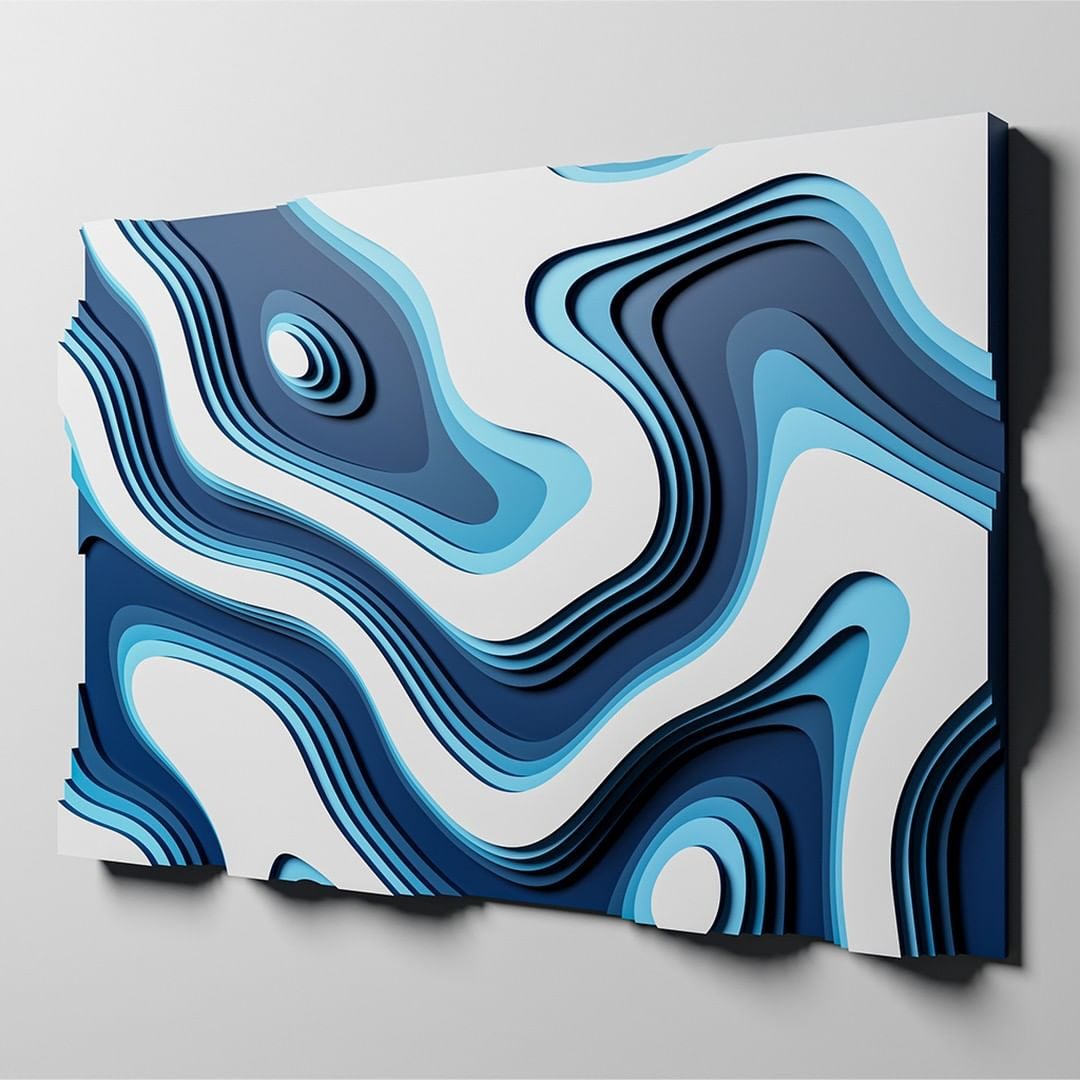

Large Wooden Wall Art

There are many small CNC made art pieces out there, but a single large art piece can really transform an entire space. Priceless.

No. 14

Traditional Canoes

Many options here, you can sell the templates for each rib segment, or you could make and sell the full boat. Even if you don't want to sell canoes, you'll probably want to make one for yourself!

No. 15

Brass Challenge Coins

The Roman Empire rewarded soldiers with challenge coins. Now organizations use them to reward their members.

No. 16

Custom Kitchens

Here's a tip: You don't need to install kitchens your self. If you work with contractors in your area, they'll already have the customers. You just mill the parts, and the contractors install them.

No. 17

Coffee Ground Sunglasses

Yep, coffee. Used coffee grounds are compressed, then milled into the desired shape. Just goes to show that your imagination is the only limit when you have a CNC.

No. 18

Guitars

If you're a maker who's also a guitarist, this one sounds pretty good!

No. 19

Custom Car Parts

This is a category where creativity shines. You can make everything from accessories to literal engine parts. The more you research, the crazier the ideas get.

No. 20

Brass Knuckles

Historic war significance, unique piece of metal, questionable legality.. What's not to love! Another popular item in the EDC community.

No. 21

Bedside Organizers

Speaking so much of EDC, where are your customers going to put all the gadgets you made for them? They'll need bedside storage as well!

No. 22

Furniture

CNC furniture makers turn art into function. This space is filled with wild ideas not limited by size or shape (or price).

No. 23

Brass Hardware

Handles, doorknobs, hinges, etc. A quality piece of brass can change the entire experience of interacting with a door or cabinet.

No. 24

Surfboards

There's many construction methods that work. You could use solid balsa wood for the whole thing, wood ribs with a hollow interior, or experiment with modern materials.

No. 25

Personalized Cutting Boards

It's a classic CNC product because it works. Consumers want them, and you can easily start by selling them at your local farmers market.

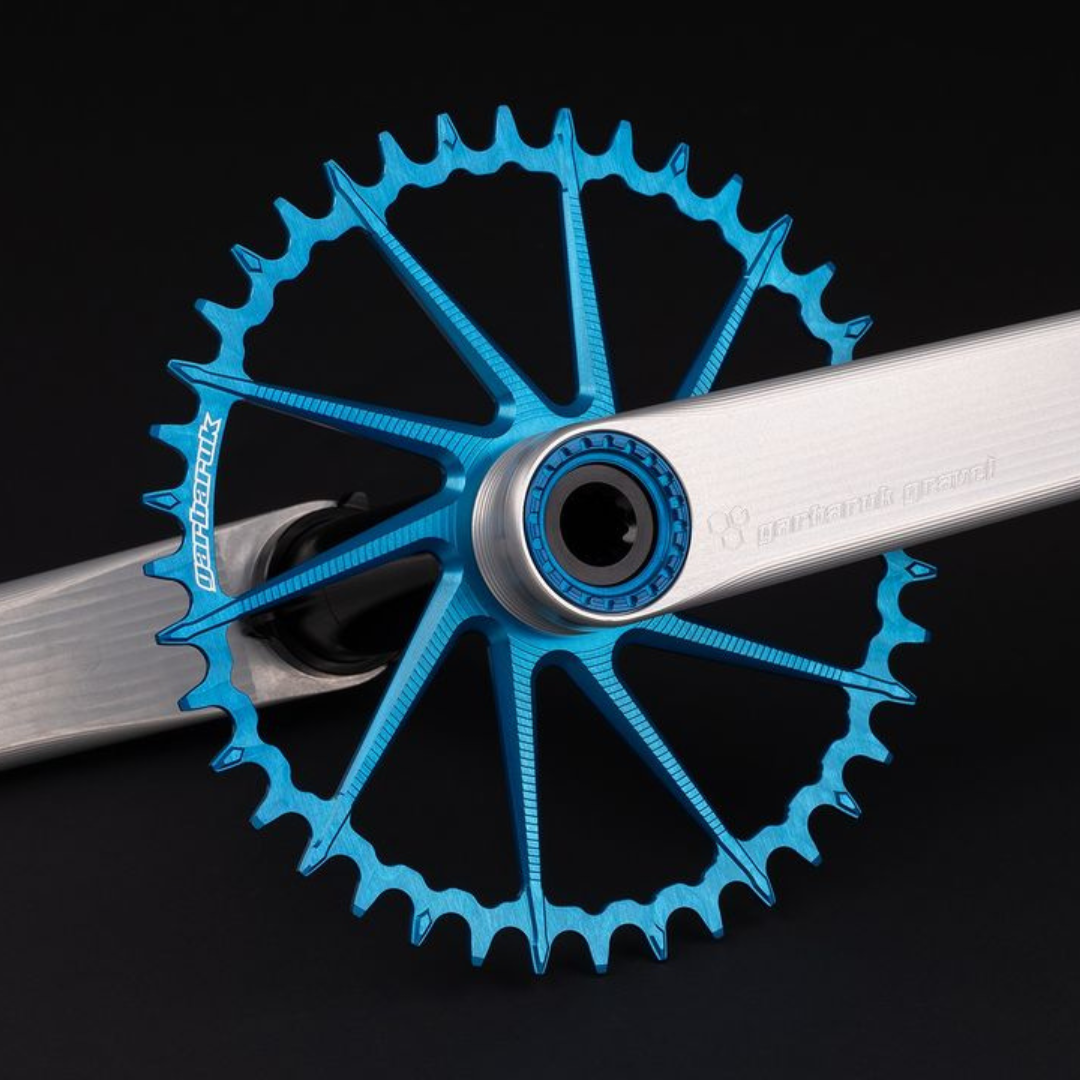

No. 26

Bicycle Parts

This is another area where makers are designing incredible items. Cycling sports come with a hefty price tag. Consumers are willing to pay for a shiny new toy.

No. 27

Slingshots

Everyone always wanted one as a kid. You'll find they are popular in social media. They'll always be fun to play with, and if you combine that with a beautiful design, you've got a winner!

No. 28

Electronics Mounting Hardware

Building a PC? Adding navigation to your boat? Need to mount multiple monitors? Many people want a custom build but if they want to do it right, they need CNC.

No. 29

Wooden Kitchen Utensils

There's a movement to remove plastics and synthetics from the kitchen environment. Stainless cookware has seen a resurgence, Pretty sure consumers will need the eutensils as well!

No. 30

Machine Parts

You can use a CNC machine mill parts to make other machines. We've seen our own customers successfully use their CNC ONE Machines to make parts for machines and robots in factories.

No. 31

Aluminum Molds

If you can mold it, you can make it. Molds allow you to create products out of all sorts of materials. Fiberglass, carbon, silicone, plastic, etc.

No. 32

Camera Hardware And Accessories

Professional photographers and videographers set up camera rigs to help them get the job done. These are mostly made from machined aluminum. A custom one sure would be special!

No. 33

Prototypes

CNC Machines a perfect for creating prototype devices. It's quite common for machine shops to set themselves up for designing and manufacturing prototypes for customers.

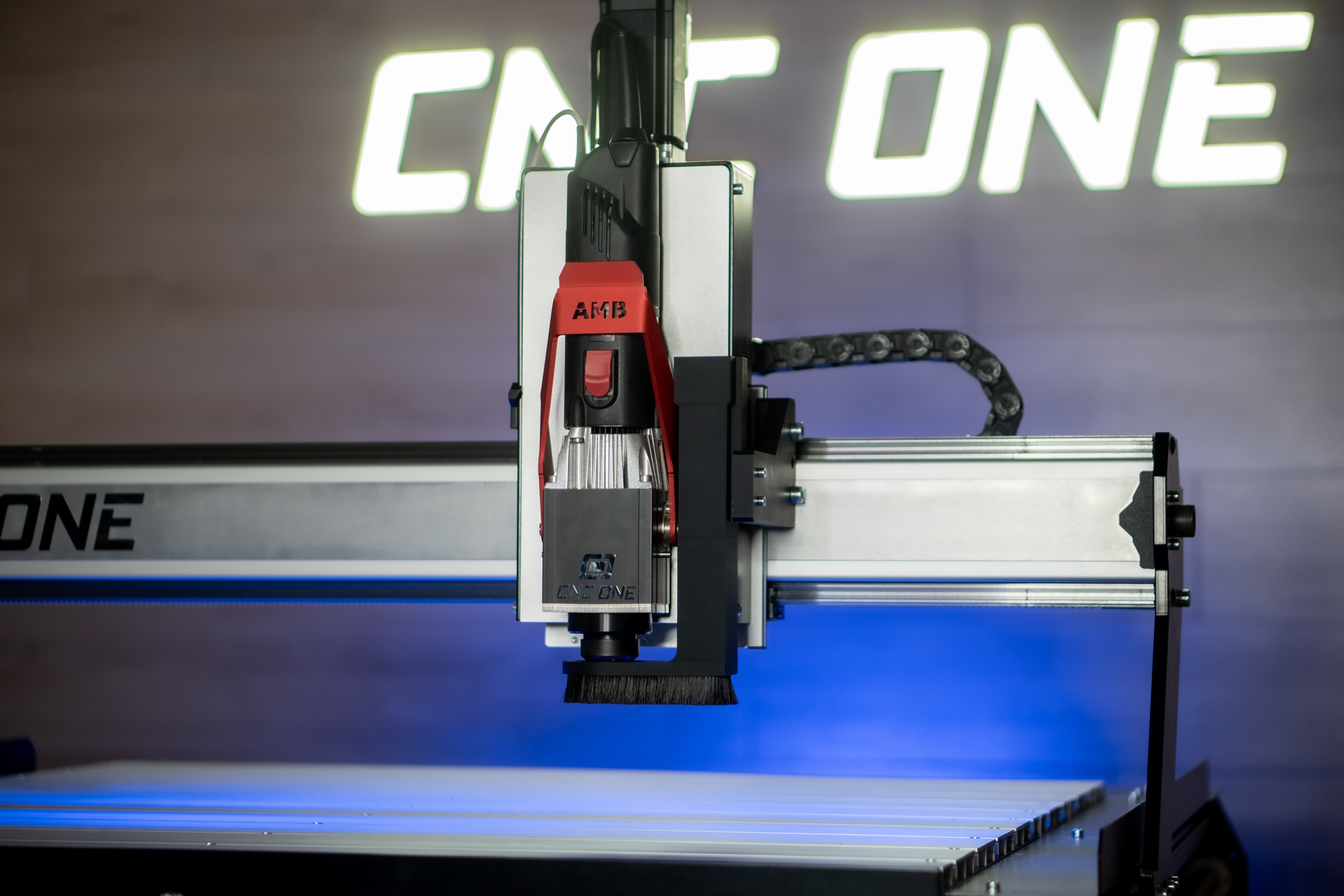

Step 3: Choose The Best Tool For The Job

Business Is Hard...

Give Yourself The MAXimum Advantage.

The truth is..

You don't know all the challenges that will come as you build a CNC business.

You'll start with one idea, but end up building another.

You may encounter sudden opportunities or trouble along the way.

The best CNC Machine for business is one that you could rely on to tackle any job.

That's CNC ONE MAX.